Galaxy Stamping Pvt. Ltd. is a leading manufacturer of electrical laminations , continuously engaged in enhancing technology and has a vast experience in a never-ending efforts to improve product quality. To maintain that position and highest level of competitiveness , we offer expertise in materials and tooling design, and value-added services.

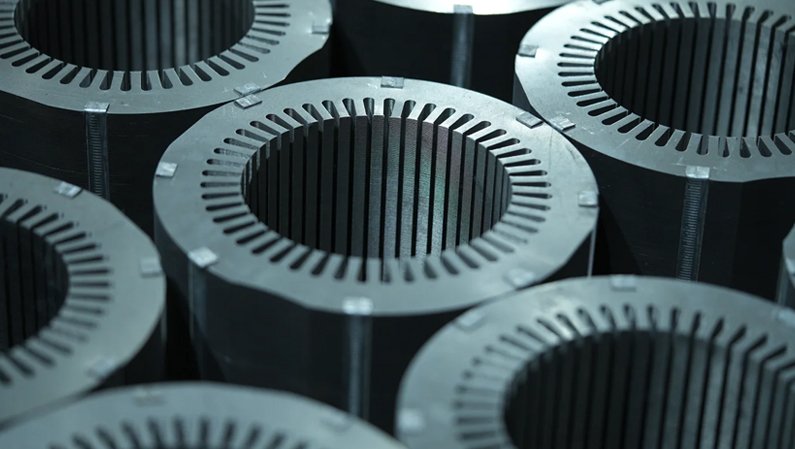

Galaxy Stamping Private Limited is a trusted manufacturer of high-precision motor stamping components, catering to a wide range of electrical motor applications. With advanced stamping technology and strict quality control, we deliver reliable and dimensionally accurate laminations that ensure optimal motor performance and efficiency.

Know More

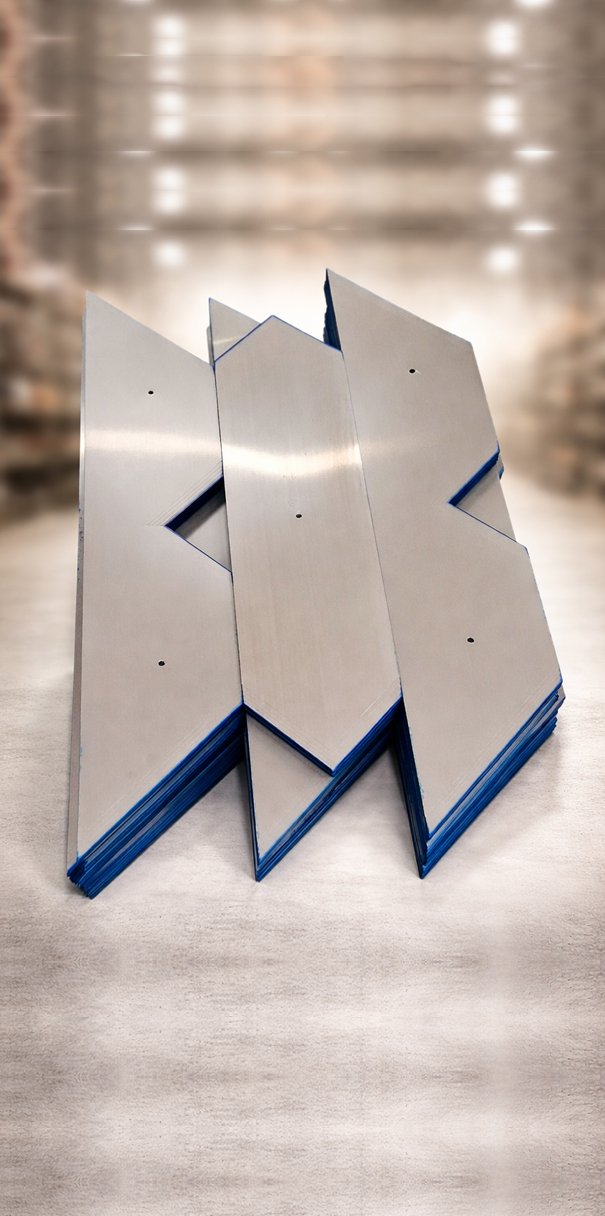

CRGO (Cold Rolled Grain Oriented) Electrical Steel is a specialized material widely used in transformer cores due to its superior magnetic properties, low core loss, and high permeability. At Galaxy Stamping Private Limited, we offer end-to-end CRGO processing solutions—from raw material handling to finished transformer core assemblies—ensuring high efficiency, precision, and reliability.

Know More

M/s Galaxy Stamping Pvt. Ltd – a leading manufacturer in electrical stampings & laminations having its facilities located at Metoda GIDC – Rajkot, was established in the year 2004 by our founder and Managing Director Mr. Chintan Sitapara.

Complete Projects

Active On Clients

Experience Team

Winning Awards

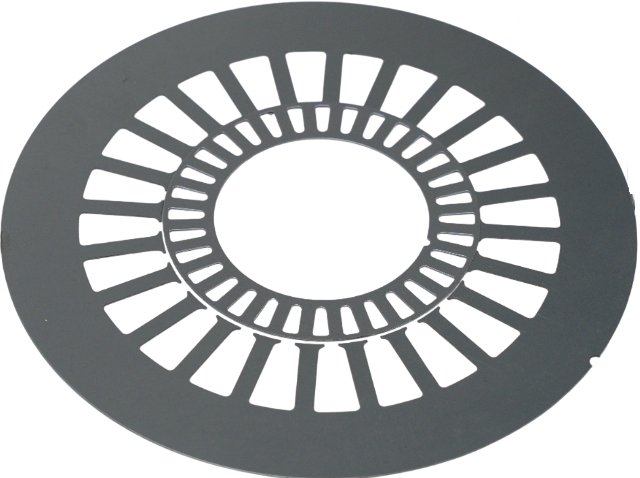

Providing precision stamping solutions for Submersible Pump Sets and Domestic Appliances industries with consistent quality and high reliability.

Stamping services for Fans, Blowers & Ventilators, ensuring high-precision, balanced, and durable metal components.

Stamping services for Induction Motors, Compressors & Generators, providing high-precision, reliable, and long-lasting metal components.

Stamping services for Transformers & Ballasts, delivering high-precision, efficient, and durable laminated components.

Stamping services for Linear Drives, Servo Motors & Traction Motors, ensuring high-precision, high-performance, and reliable laminated components.

Stamping services for Aerospace & Automotive Products, delivering high-precision, safety-critical, and performance-driven components.